A16-1

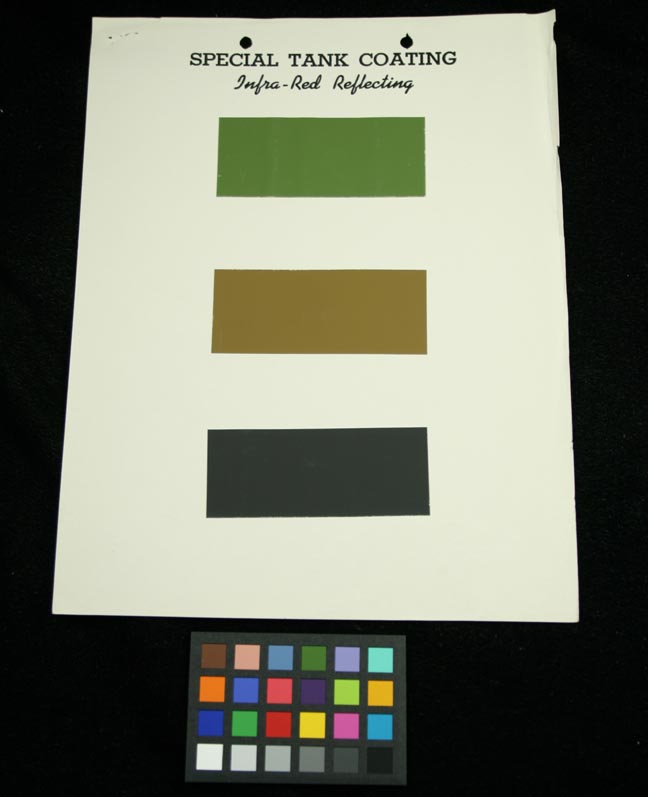

3. Information in the possession of this Bureau indicates that the heat reflectivity of dark color paints is greatly increased if the particular paint employed possesses the property of reflecting infra-red radiation. At present the only commercially available dark color, infra-red reflecting paint known to the Bureau is a special tank coating manufactured by the Arco Company of 7301 Bessemer Avenue, Cleveland, Ohio and 745 East 59th Street, Los Angles, California, This coating is available in green, brown and black as shown on enclosure (A). It is understood that the three colors shown can be mixed together to obtain shades similar to those contained on the green and brown color charts contained in reference,(b), but that the coating cannot be mixed with other paints or colors in oil without destroying the infra-red reflecting properties. The coating can be made in special colors by the manufacturer, if the range obtainable with the three colors shown is deemed insufficient.

4. It should be noted that it is only the final coat of paint that determines the heat-reflecting characteristics of a surface, and therefore the special infra-red reflecting tank coating discussed above may be applied directly to previously painted surfaces, and must not be covered with any other coating. This type of paint is not applicable where splinter-proofing on side-walls of tanks is in place, 5» Enclosure (B), Tentative Memorandum Specification for Infra-red Reflecting Paint, is forwarded for information, The Bureau is cooperating in investigations being carried on with a view to establishing more fully developed specifications for infrared reflecting paint.

![]()

Assistant to Chief of Bureau

By direction.

Distribution:

All Bureaus and Offices;

Addressees on List "B".