| RESTRICTED M.P.D.H #l-Sup.No.2 |

- 15 - |

If you can see this text here you should update to a newer web browser

Normal | Highlight & Comment Highlighted Text will be in Yellow.

|

CAMOUFLAGE PAINTS AND PAINTING FOR SHORE ACTIVITIES

NAVY PASSIVE DEFENSE HANDBOOK NO. 1 (SECOND SUPPLEMENT)

RESTRICTED

Prepared by the Bureau of Yards and Docks

December, 1941

|

CAMOUFLAGE PAINTS AND PAINTING FOR SHORE ACTIVITIES Table of Contents

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CAMOUFLAGE PAINTS AND PAINTING

SCOPE OF THIS SUPPLEMENT 1. This supplement amplifies the discussion of camouflage paints and painting presented in paragraphs 74 - 80 of Navy Passive Defense Handbook No. 1, and is concerned primarily with the application of paint to buildings and to oil and gas tanks. Especial attention is called to Paragraphs 7 and 8 on use of soil coloration as a paint substitute, to Paragraphs 14 through 17 on use of infra-red paint on tanks containing volatile liquids, and to Paragraphs 18 and 19 on precautions against detection of camouflage by infra-red photography.

|

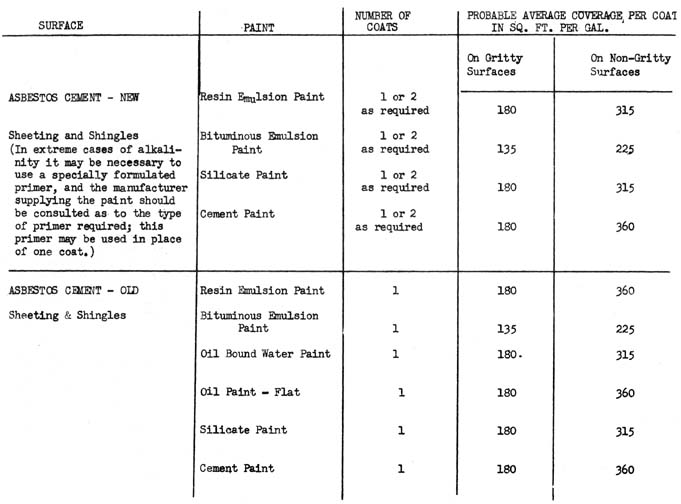

TECHNICAL NOTES ON THE APPLICATION OF CAMOUFLAGE PAINT 2. Types and Coverage of Paint: The types of paint suitable for use on various materials are shown in Table I, together with data on the number of coats required and the coverage per gallon. For most materials enough varieties of paint are recommended to give considerable latitude in selection; however, the order of preference of paint types is shown for each material and should be given due consideration. For specifications of the various paints, insofar as they are available at this time, see Paragraphs 21 to 45 below. 3. It will be noted that the coverage per gallon shown in Table I is consistently lower than the normal standards of the Bureau. This is because single coats only are applied in most cases, and the coverage must necessarily be less to obtain sufficient density in one application. Even on new unpainted surfaces, which would normally receive one primer and two full coats, only one or two coats is stipulated (one of which may be a primer), for the reason that seasonal changes may necessitate seasonal variation of color.* 4. The Measurement of Specular Reflection: As pointed out in N.P.D.H. No. 1, Paragraphs 14 - 17, painted surfaces must be considered from the standpoint of texture, and every effort must be made to develop "mattness" and to avoid specular reflection, or "gloss". In determining the suitability of a certain paint for camouflage purposes, therefore, it is frequently desirable to measure the specular gloss associated with it. This may conveniently be done by means of the improvised apparatus shown in Fig. 1. For the test, the paint is applied to the smooth metal panel and allowed to dry for 24 hours at ordinary room temperatures. The panel is then placed horizontally in the apparatus, as shown, and the maximum angle at which a reflected image of the graining comb can be seen is noted. This angle is a measure of the specular gloss; for non-gritty camouflage paints it should not exceed about 20°, and for gritty paints it should not exceed 10°. 5. Admixtures to Reduce Specular Reflection: In order to reduce specular reflection on painted surfaces, foreign materials may be mixed into the paint to create a matt surface. The materials may vary, according to availability and the texture desired

|

and may comprise sand, sawdust, cork dust, rice husks, wheat chaff, wood pulp;, etc. They may be pre-colored, and broadcast over the surfaces of wet paint either by hand or by mechanical means, or they may be introduced into the paint mixer and sprayed, provided suitably designed nozzles are used. Care must be taken that the paint has sufficient body to hold the materials in suspension; otherwise they will tend either to float or to sink, and may clog the nozzles. Frequent agitation is necessary in any case. 6. In Table I, the coverage per coat of paint for "gritty surfaces" applies both to surfaces where the grittiness is obtained by introducing particles into the paint and to surfaces previously roughened by a coating of sand in varnish or some similar material. Coarser surfaces than these, obtained by applying "chippings" to treated surfaces, will require somewhat more paint than indicated in the table. 7. s"Soil Coloration" as a Paint Substitute: In extreme emergency, where sufficient paint is not available to complete a scheme of camouflage, "soil coloration" may be resorted to. This process consists of mixing local soil with a proportion of cheap, lime-free pigments, adhesive, and water, and painting or spraying the mixture over the entire surface of structures. The scheme is not very desirable, and its permanence is low in regions where there is any appreciable rainfall. However, it will provide a measure of protection in emergency. The adhesive referred to above may be a dilute solution of bituminous emulsion primer or bituminous emulsion paint. Care nmst be taken not to use an excessive amount; otherwise there will be difficulty in removing the soil preparatory to more permanent painting.8. Protecting Expensive Facades from Camouflage Discoloration: In applying camouflage paint or "soil coloration", ornamental facades or expensive facings may be protected from discoloration (though at considerable cost) by covering them with building paper, sisal kraft paper, or laminated wire paper, attached to light wooden battens and netting or to wire. The paper surfaces may then be painted as desired; There must be sufficient overlap between sheets to prevent paint from finding its way through the seams, and the upper strakes of paper should overlap the lower for proper drainage. 9. Window Treatment:* Translucent paint, applied to the

|

exterior surfaces of glaring, will eliminate a considerable part of the reflection of the direct rays of the sun or moon, while atill permitting considerable light to enter the building. The reflection may be still further reduced by texturing the paint with sand particles of about 60 - 80 mesh. These particles will not shine, provided they are thoroughly coated with the paint. 10. Either "clear-water" (colorless) or tinted translucent paint may be used, depending on the requirements of the general camouflage scheme. In emergency the other paints listed in Table I for use on glass surfaces will serve the same purpose, if properly tinted and thinned. 11. Another method of eliminating glint without completely blocking the admission of daylight to the building employs nets hung about 12 inches in front of the glazing. These nets may be of the heavy woven rope variety or of garnished chicken-wire and must be securely fastened to the building to prevent damage or destruction by wind. 12. In planning the camouflage of buildings it should be remembered that windows normally appear dark during daytime. For this reason, light-colored parts of the general pattern must be carried over the glazing, whereas in the darker parts of the pattern the glazing need only be treated with "clear-water" translucent paint to prevent glint. 13. In window painting of any description, framing that forms a part of the window opening should be painted flat black or in color, depending upon its position in the pattern.14. Painting of Fuel Storage Tanks. In general, dark color paints do not possess as high a degree of heat reflectivity as aluminum paint. Consequently, the camouflage painting of fuel storage tanks with "ordinary" materials is likely to cause a rise in the temperature of the tank contents; and this rise may be sufficient to evaporate certain important components of the gasoline and thus reduce its efficiency as a fuel. 15. Information in the possession of the Bureau indicates that the heat reflectivity of dark paints capable of reflecting infra-red radiation is considerably greater than that of paints lacking this property. For tentative specifications for such paints see Paragraphs 44 to 45 below.

|

16. At present the only commercially available, dark-color, Infra-red-reflecting paint known to the Bureau ie a special tank coating manufactured by the Arco Company of 7301 Bessemer Avenue, Cleveland, Ohio, and 745 East 59th St., Los Angeles, California. This coating is available in black and in one shade each of brown and green. It is understood that these three colors can be mixed together to obtain shades similar to those on the green and brown color chart of N.P.D.H. No. 1, but that the coating cannot be mixed with other paints or with colors in oil without destroying the infra-red-reflecting properties. The coating can be made in special colors by the manufacturer, if the range obtainable by the means just described is deemed insufficient. Link to last document here 17. It should be noted that it is the final cost of paint that determines the heat-reflecting characteristics of a surface, and that the special coating discussed in the preceding paragraph may therefore be applied directly to previously painted surfaces without loss of effect, but must not be covered with any other. 18. Precautions Against Detection of Camouflage by Infra-Red Photography: Deciduous foliage photographs white under infra-red photography, whereas green painted surfaces in general photograph dark, just as when using ordinary panchromatic film.* Hence where structures are painted green to make then blend with grass areas or other planting, or where steel wool, garnishing cloth, or other camouflage materials are painted green to simulate desiduous vegetation, the camouflage is likely to be revealed by infra-red photography unless an infra-red-reflecting green paint is used. The availability of such paint is discussed in Paragraph 16 above and tentative specifications are presented In Paragraphs 44 and 45 below. 19. It should be noted that pines and other coniferous trees do not photograph white under infra-red, but possess photographic tonal values similar to those of surfaces painted with ordinary green paint. Therefore infra-red-reflecting paint should not be used for structures or camouflage installations situated amidst coniferous growth.

|

PAINT SPECIFICATIONS AND MISCELLANEOUS COMMENTS Start here21. General; Paints of the types listed in Table I are discussed in the following paragraphs, and specifications are included — either directly or by reference — where available. It is to be noted that certain of these specifications are at present tentative only. 22. Copies of specifications may be obtained by manufacturers or others as follows:

23. Resin Emulsion Paint; Federal Specification TT-P-88 for "Paint, resin-emulsion, interior paste, light tints and white" dated December 27, 1940. This paint, though classified by the specification as an interior paint, is recommended for exterior use for camouflage purposes without modification. It is dull and lustreless. It may be purchased in white or light tints and should be blended with suitable lime-proof pigments to match the standard camouflage colors (see color charts at end of N.P.D.H. No. 1). In matching colors, small quantities of pigment should be added on a trial-and-error basis. The final consistency of the paint should be in accordance with the requirements of Paragraph E-l-c of the referenced specification. 24. The following are some of the manufacturers of this type of paint:

|

||||||||||||||||||||

25. Cold-Water Paint: Federal Specification TT-P-23a for "Paint, cold-water, interior, light tints and white" dated March 22, 1940. This paint, which is dull and lustreless, may be purchased from most paint manufacturers in either powder or paste form and in almost any color desired. If blending is necessary to match the standard camouflage colors the pigments should be added in small quantities on a trial-and-error basis, and the final consistency of the paint should be in accordance with the requirements of Paragraph E-2-c of the specification. This paint should not be applied in freezing weather, and extremes of either heat or cold should be avoided in storing it. 26. Oil Paints: Oil paints produced according to the Federal Specifications listed below all have a glossy finish and must be modified to produce the flat, lustreless surface required for camouflage purposes. Specifically, the specular gloss of the unmodified paints registers about 50 on a 60° Hunter portable gloss meter; this value must be reduced to not more than 10 before the paint is suitable for camouflage application. An improvised apparatus for measuring gloss has already been described in Paragraph 4; methods of reducing gloss are discussed below, following the list of specifications;

|

||||||||||||||||||||||||||||||

27. The gloss of ready mixed oil paints may be reduced by adding dry earth pigments such as whiting, ochre, umber, sienna, Indian red, chrome green, or other desired colors. (Dry white lead does not reduce gloss materially, on account of its low oil absorption.) To 100 lb. of the ready mixed paint from 20 to 35 lb. of the dry pigment may be added. In matching colors, the pigments should be added in small quantities on a trial-and-error basis and the final consistency should be in accordance with the brushing, spraying, flowing, spreading, and recoating clauses of the specifications. If the paint gets a little heavy, a small quantity of turpentine or mineral spirits and drier should be added. (Linseed oil should not be used.) This will produce a flat and lustreless aurface with a gloss reading of about 10, which will be further reduced by weathering. 28. Where dry earth pigments are not available, specular gloss may be reduced (in an emergency) by adding 25 lb. of dry portland cement to each 100 lb. of mixed oil paint and pigmenting with oil-paste pigments. This mixture may be thinned by adding turpentine, mineral spirits, and drier (omitting linseed oil). It appears that this will reduce the gloss to about 25 which, though not satisfactory, is passable in emergency. 29. Semi-paste oil paints are preferable to ready mixed paints for camouflage purposes, and when reduced with turpentine, mineral spirits or other volatile thinner, and a liberal quantity of drier, and properly pigmented with dry earth pigments, they will produce a flat, lustreless surface. 30. If either a ready mixed oil paint or a paste is colored with oil-paste pigments, the process of thinning does not reduce gloss sufficiently for camouflage purposes, for the reason that nothing is added to act as an oil absorbent.

|

31. Special Flat Camouflage Paint: The following formula for a quick-drying, flat and lustreless oil paint for use on buildings is similar to one used extensively by various branches of the government during the World War:

The paint should be of brushing consistency and should dry within four hours to a flat, non-reflecting surface (gloss not more than 5 per mil). 32. Bituminous Paints: Approved specifications for paints of this class are not yet available. 33. These paints are quite dull and lustreless, and are suitable for use on almost any surface.* They are obtainable in a limited range of colors, mostly dark; these may be pigmented to lighter shades if desired, but at the cost of reducing the durability of the paint. Pigments and thinners should be obtained from the manufacturers at the time of purchase. (It is to be noted that the lighter colors now on the market have a tendency to lighten still further on exposure.)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

34. The American Bitumuls Company is one of the manufacturers of this class of paint. Addresses of the home office and branches of this company are as follows:

The Bureau has not yet had an opportunity to ascertain what other manufacturers are producing bituminous paint at this time. 35. Silicate Paints: Approved specifications for paints of this class are not yet available. 36. Cement Paint: Federal Specification TT-P-21 for "Paint, cement-water, white and tints" is now (September 1941) being printed. 37. Cement paint is flat and lustreless, and is classified for use on porous surfaces of brick, masonry, concrete stucco, and rough plaster. It is obtainable in white or tints and should be blended with suitable lime-proof pigments to match the standard colors. In matching, small quantities of pigment should be added on a trial-and-error basis, and the final consistency of the paint should be in accordance with the requirements of Paragraph E-l-b of the specification. It is to be noted that unless special precautions are taken, cement paints are apt to lose their color through efflorescence or "blooming". 38. This type of paint is obtainable from most paint manufacturers. 39. Translucent Paints: Translucent paints are in an experimental state of development in the United States, but have been used successfully in Great Britain. No specifications are as yet available. 40. These paints are recommended for treatment of glass surfaces where minimum reduction of the passage of daylight is desired. 41. Synthetic Enamel and Primer (Olive Drab for Motor Vehicles); Quartermaster Corps Tentative Specification ES-No. 359b for "Primer,

|

synthetic, rust-inhibiting" and ES-No. 474b for "Enamel, synthetic, olive drab — lustreless". 42. This primer and enamel should be used without modification and full instructions are given in the specifications. Where surfaces of automobiles or trucks are already painted, the priming coat is not necessary. 43. The primer specification contains a "list of approved suppliers". 44. Infra-Red-Reflecting Paint: Approved specifications for paint of this type are not yet available. The following paragraph is tentatively suggested, however, as an addition to any standard government paint specification when the property of infra-red reflection is desired: The paint shall have an infra-red reflection factor of not less than 1.00 as determined by the following method: DESCRIPTION OF APPARATUS AND METHOD OF DETERMINING THE INFRA-RED REFLECTION FACTOR OF PAINT Light: An even source of infra-red illumination is required. This can be obtained by the use of Mazda lamps which are an efficient source of infra-red light. To secure even distribution of light a "doughnut" type of light source such as used in photographic copying is quite satisfactory. Camera: Any camera can be used providing it takes cut film. Film: Eastman Infra-red Cut film. Developer: Fresh DK-50 for 10 minutes at 70° with agitation every two minutes. It is important that the developer be used only once. Filter: Wratten #87. Exposure: Determine by means of Weston Exposure Meter using Weston film speed of 1.5 for this film and filter.

|

Procedure: Lay the panels on the base board and include with these panels a piece of black velvet approximately the same size as the panel to be tested. Make the exposure, develop, fix and dry as specified above. Measure the density on the negative of the image of the black velvet and the density of the image of the painted panel by means of any standard densitometer. The infra-red reflection factor is the difference between the two density readings obtained on the densitometer. 45. When specifying infra-red-reflecting characteristics in paint, it is advisable not to limit the type of pigments that may be employed.

|

TABLE I. CAMOUFLAGE PAINT RECOMMENDATIONS FOR VARIOUS STRUCTURAL SURFACES

For each structural surface, the recommended paints are listed in order of preference. Types of paint not listed for a given surface should not be used for the surface except in extreme emergency.

|

||||||||||||||

|

Note: Rotated copy of the below image is available here.

|

Note: Rotated copy of the below image is available here.

|

Note: Rotated copy of the below image is available here.

|

Note: Rotated copy of the below image is available here.

|

Note: Rotated copy of the below image is available here.

|

Note: Rotated copy of the below image is available here.

|

|

||||||||||||||||

SOURCE:

National Archives & Records Administration, Seattle Branch

Record Group 181, Puget Sound Naval Shipyard Captain of the Yard Passive Defense Files

Transcribed by RESEARCHER @ LARGE. Formatting & Comments Copyright R@L.

Miscellaneous Home | Passive Defense Home | Researcher@Large Home